P50 Rail

P50 rail is a type of heavy-duty rail that is widely used in various industries. It is known for its high load-bearing capacity and durability. This article provides detailed information about the P50 steel rail, including its chemical composition, mechanical properties, applications, and precautions for use.

P50 steel rail is manufactured from high-carbon alloy steel with the following primary chemical composition:

- Carbon (C): 0.65% – 0.77%

- Manganese (Mn): 1.10% – 1.50%

- Silicon (Si): 0.15% – 0.35%

- Phosphorus (P): 0.04%

- Sulfur (S): 0.04%

- Other elements: 0.20%

P50 rail is a type of heavy-duty rail that is widely used in various industries. It is known for its high load-bearing capacity and durability. This article provides detailed information about the P50 steel rail, including its chemical composition, mechanical properties, applications, and precautions for use.

Classification

P50 rail falls under the category of heavy-duty rails. These rails are commonly used for constructing railways, main tracks, and tunnels, or as crane rails for tower cranes, overhead cranes, gantry cranes, etc. Heavy-duty rails are usually made from U71Mn or 50Mn steel and have lengths ranging from 12.5 to 25 meters. Some typical examples of heavy-duty rails include the P38 rail, the P43 rail, and the P50.

| Heavy Steel Rail Type | Classification |

|

|

|

|

|

|||||

| 38kg | 134 | 114 | 68 | 13 | 38.733 | ||||||

| 43kg | 140 | 114 | 70 | 14.5 | 44.653 | ||||||

| 50kg | 152 | 132 | 70 | 15.5 | 51.514 | ||||||

| 60kg | 176 | 150 | 73 | 16.5 | 60.8 | ||||||

| 75kg | 192 | 150 | 75 | 20 | 74.64 |

Chemical Composition of P50 Rail

P50 steel rail is manufactured from high-carbon alloy steel with the following primary chemical composition:

- Carbon (C): 0.65% – 0.77%

- Manganese (Mn): 1.10% – 1.50%

- Silicon (Si): 0.15% – 0.35%

- Phosphorus (P): 0.04%

- Sulfur (S): 0.04%

- Other elements: 0.20%

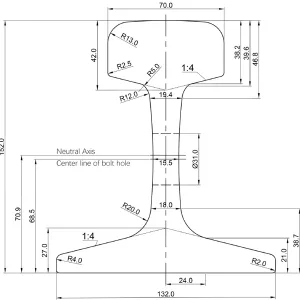

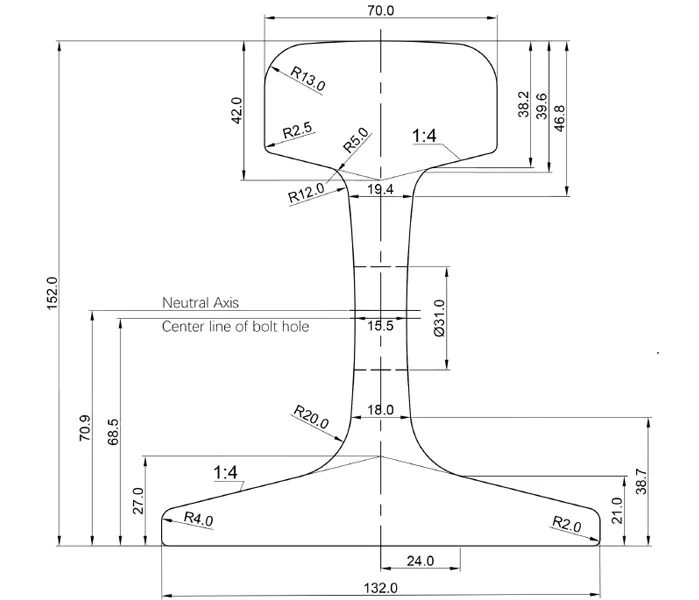

Rail Specifications

| Parameter | |||

| Type | Weight (kg/m) | Material | Length (m) |

| 50kg | 51.514 | 50Mn/U71Mn | 12m/12.5m |

| Rail Height (mm) | Bottom Width (mm) | Head Width (mm) | Thickness (mm) |

| 152 | 132 | 70 | 15.5 |

=>>>> READ MORE: STEEL RAIL SPECIFICATION

Mechanical Properties

Owing to its optimized chemical composition, the P50 steel rail possesses impressive mechanical properties:

- Ultimate tensile strength: ≥500 MPa

- Ultimate bending strength: ≥420 MPa

- Minimum elongation: 14%

Applications

With its high load-bearing and pressure-resistant capabilities, the P50 steel rail finds widespread application in various fields:

- Rail Transportation:

- Internal goods transportation within factories, quarries, and mining areas.

- Used as crane tracks in workshops.

- Slide Rails:

- Utilized for transporting goods in warehouses and docks.

- Temporary transportation paths in construction projects.

- Industrial Framework:

- Used in the fabrication of frames for heavy industrial equipment.

- Frame construction for machinery and equipment within factories.

Considerations for P50 Steel Rail Usage

To ensure safety and efficiency when using P50, the following points should be considered:

- Storage:

- Store the P50 steel rail in a dry, well-ventilated place, avoiding direct contact with water and chemicals.

- Regularly lubricate the steel rail to prevent rust and enhance durability.

- Inspection:

- Thoroughly inspect the quality of the steel rail before use, ensuring it is not bent, warped, cracked, or rusted.

- Use suitable equipment for lifting and transporting steel rails.

- Construction:

- Construct P50 steel rail according to technical standards, ensuring flatness and safety.

- Use appropriate bolts and screws to connect rail segments securely.

Thank you for reading this article. Please follow us on our WEBSITE or social media platforms such as FACEBOOK, LINKEDIN, and YOUTUBE for new articles with useful information.

==>> READ MORE: P18 STEEL RAIL

==>> READ MORE: P24 STEEL RAIL

==>> READ MORE: P30 STEEL RAIL