15 Ton Gantry Crane – Detailed Specifications

Technical Datasheet for 15-Ton Gantry Crane

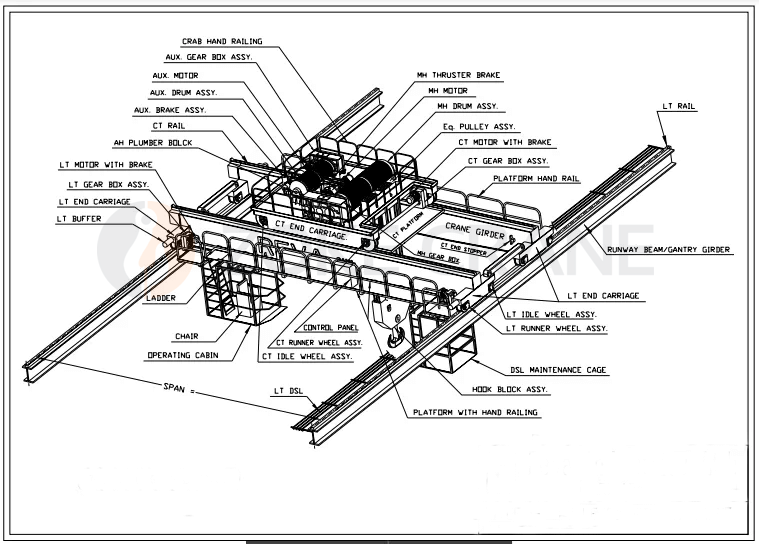

Equipment Type: Double-girder Gantry Crane

Model Code: COK15T

Applicable Standards

- Design and Manufacturing Standard: FEM 1.001, TCVN 4244-2005

- Surface Preparation and Painting Standard: ISO8501, SSPC SP10

- Inspection and Certification for Use: Safety Inspection Center

Technical Datasheet for 15-Ton Gantry Crane

Equipment Type: Double-girder Gantry Crane

Model Code: COK15T

Applicable Standards

- Design and Manufacturing Standard: FEM 1.001, TCVN 4244-2005

- Surface Preparation and Painting Standard: ISO8501, SSPC SP10

- Inspection and Certification for Use: Safety Inspection Center

Crane Operating Modes

- Gantry Crane Operating Mode: FEM 4m

- 15-Ton Hoist Operating Mode: FEM 4m

Main Girder Stiffness: 1/1000

Quantity: 1 set

Installation Location: Outdoor

Rated Lifting Capacity: 15 tons

Hook Type: Single Hook

Rail Length: 100 m

Lifting Height: 26 m (+10 m, -16 m)

Span: (23 + 4) m

Power Supply: 380 Volts, 3 Phase, 50 Hz

Relay Control Power: 24 Volts

Control Power: 220 Volts

Remote Control (Details as per Control Description)

- Main Control: 1 unit / Joystick type

- Auxiliary Control: 1 unit / Remote pushbutton type

- Load Display: 1 unit

- Load Sway Prevention System

Environment Temperature: 0°C / + 40°C

Maximum Wheel Load: 30 tons

Lifting and Travel Speeds

- Lifting Speed at Full Load: 12/2 m/min (Controlled and regulated by VFD)

- Trolley Travel Speed: 15/5 m/min (Controlled and regulated by VFD)

- Gantry Crane Travel Speed: 30/5 m/min (Controlled and regulated by VFD)

15-Ton Trolley by VINALIFT manufacturing

Manufacturer: VINALIFT

Model: VNL15H26D

Lifting Motor: 37kW / SIEMENS

Lifting Gearbox: SUMITOMO

Lifting Brake: 1 unit / Hydraulic drum brake / ZPMC

Trolley Travel Motor Gearbox: 2 units / SUMITOMO / Bonfiglioli

Trolley Travel Brake: DC Electromagnetic Brake

Lifting Hoist Rope: Korea

Hook Type: Single Hook

Lifting VFD: Yaskawa / Mitsubishi

Trolley Travel VFD: Yaskawa / Mitsubishi

Trolley Power Cable: Flat deep cable

Safety Devices:

- Overload Protection

- Lifting and Lowering Limit Switch

- Trolley Travel Limit Switch

- Gantry Crane Travel Limit Switch

- Rail Clamp

- Storm Lock

- Crane Travel Warning Siren and Lights

- Master-Slave Control Signal Lights (Green-Red-Yellow) for Remote Control

- Two-Crane Collision Avoidance Warning

- End-of-Run Limit Switch

Gantry Crane Travel Drive

- Motor Gearbox: SUMITOMO / Bonfiglioli

- Gantry Crane Travel VFD: Mitsubishi / Yaskawa

Gantry Crane Power Supply

- Type: Motorized festoon cable

- Power Supply Point: Midpoint

Gantry Crane Wheels

- Diameter: 500 mm

- Material: S45C

- Wheel Tread Hardness: 38~42HRC

- Number of Wheels: 4

Steel Structure and Materials

- Steel Structure: SS400/Q235B

- Handrails and Work Platforms: SS400/Q235B

- Main Girders and Leg Girders: Box girders, welded joints are segmented with lengths less than 12 m (for containerized shipping) and bolted for easy disassembly and movement between job sites

- Bolts: Grade 8.8, hot-dip galvanized

- Non-destructive Testing of Welds:

- Butt welds: 100% UT

- Fillet welds: 25% MT

- Crane Rails: P43

Surface Preparation and Painting

- Surface Preparation: Sa 2.5

- Paint Type: Epoxy

- Color: RAL 1004

15-Ton Gantry Crane Control Description

The 15-ton gantry crane includes systems for traveling the long trolley, traveling the trolley, and raising and lowering the hook. The following control devices are installed on the gantry crane:

-

Central Control Cabinet: Designed with PLC connection to control crane operation and collect and store data (load, time, etc.). The HMI screen allows the operator to monitor crane operation, diagnose faults, and retrieve load data.

-

Load Sensors: Installed on each trolley to send data to the PLC

- Remote Control: Remote control units are installed on the gantry crane at the workstations, including:

-

- 1 Master Remote Control BDK 0: Provides overall control of the gantry crane operations and assigns control permissions to slave remote controls.

- 1 Slave Remote Control BDK 1 at Position 1

- Control Permission Indicator Lights:

The gantry crane is equipped with 1 set of indicator lights. Each set of lights has 3 colors: green, red, and yellow, used to indicate control positions for easy observation and operation, ensuring safety.

- Indicator Lights – DB – For Trolleys:

- Green: The Master Control Unit has control permission.

- Yellow: VT 1 / BDK1 has control permission.

- Red: Crane is stopped.

- Load Display:

Each trolley has 1 extended load display unit, allowing the operator to observe and know the lifting load for safe lifting and lowering.

Gantry Crane Control Operation Description

Remote control units operate the gantry crane.

- The Master Remote Control provides overall control of the gantry crane and can also distribute control permissions to appropriate positions, ensuring safety during operation.

The Master Remote Control is used to control the following operations:

- Gantry crane travel – when control permissions of slave BDKs have been turned off.

- Trolley travel – when control permissions of slave BDKs have been turned off.

- Hook lifting and lowering – when control permissions of slave BDKs have been turned off.

- Assign control permissions to the control units at Position 1; using the switches on the Master Remote Control.

Note:

- To ensure safety, once control permissions have been granted, the Master Remote Control will not be able to control the directions for which permissions have been granted.

- At any one time, each trolley can only be controlled by a single remote control unit at 1 position.

- Only the Master Remote Control can control gantry crane travel, on condition that control permissions from slave BDKs have been turned off.

Control System Diagram:

Benefits of Using the 15-Ton Gantry Crane:

- Improved Operational Efficiency: The gantry crane enables fast and accurate lifting and lowering of goods, saving time and labor.

- Enhanced Work Safety: The gantry crane is equipped with advanced safety devices to ensure the operator’s and goods’ safety.

- Expanded Operational Capabilities: This crane can operate in various environmental conditions, meeting diverse usage needs.

Applications of the 15-Ton Gantry Crane:

- Factories and Warehouses: The 15T gantry crane is used for lifting and lowering goods in factories and warehouses, facilitating efficient goods transportation.

- Seaports: The 15-ton gantry crane is used for container loading and unloading at seaports, saving transportation time and costs.

- Construction Sites: Lifting construction materials at construction sites, ensuring safe and efficient construction.

Thank you for reading this article. Please follow us on our WEBSITE or social media platforms such as FACEBOOK, LINKEDIN, and YOUTUBE for new articles with useful information.

In addition, you can add the following information in similar articles: (30+30) Ton Gantry Crane, 100-Ton Gantry Crane