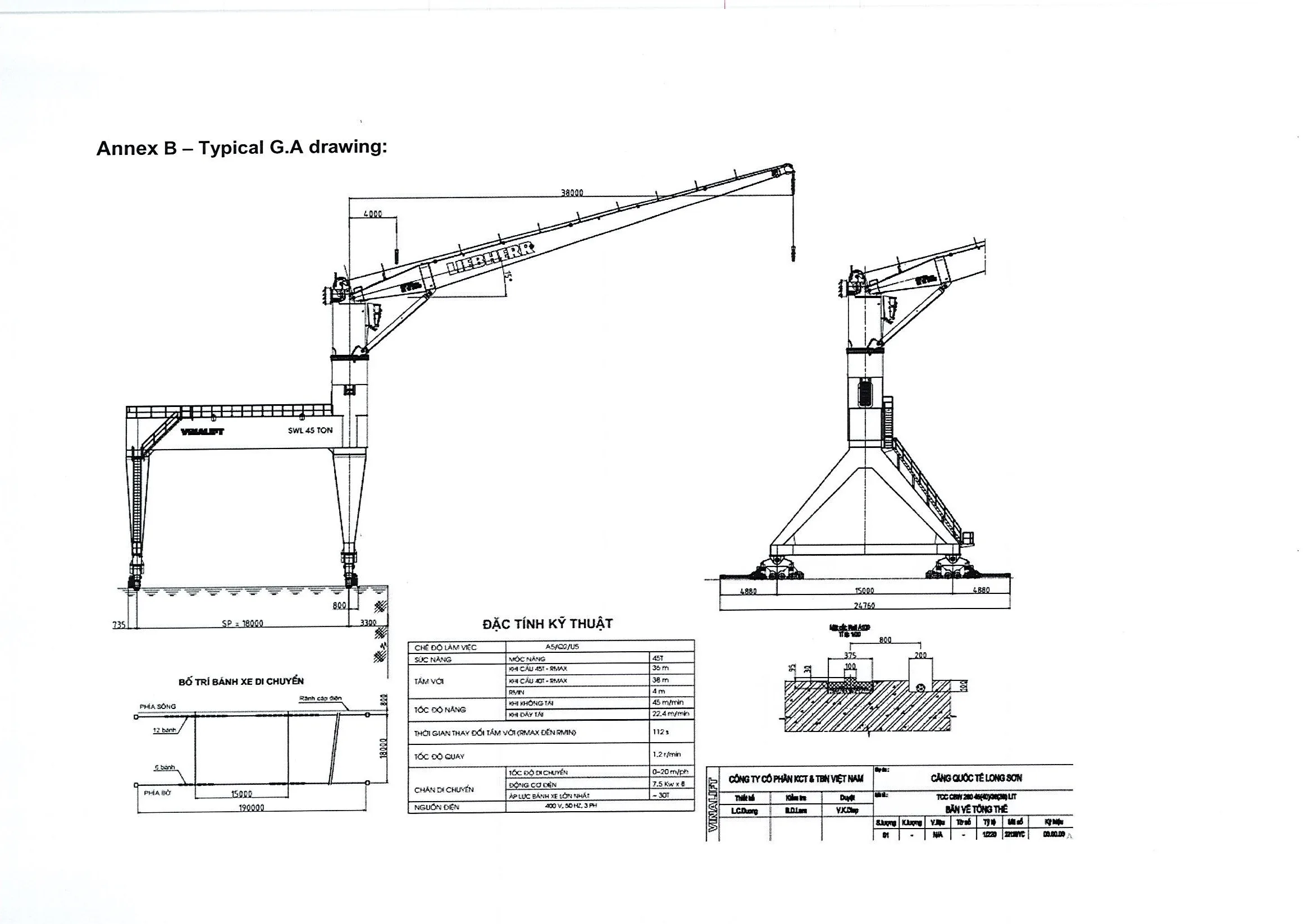

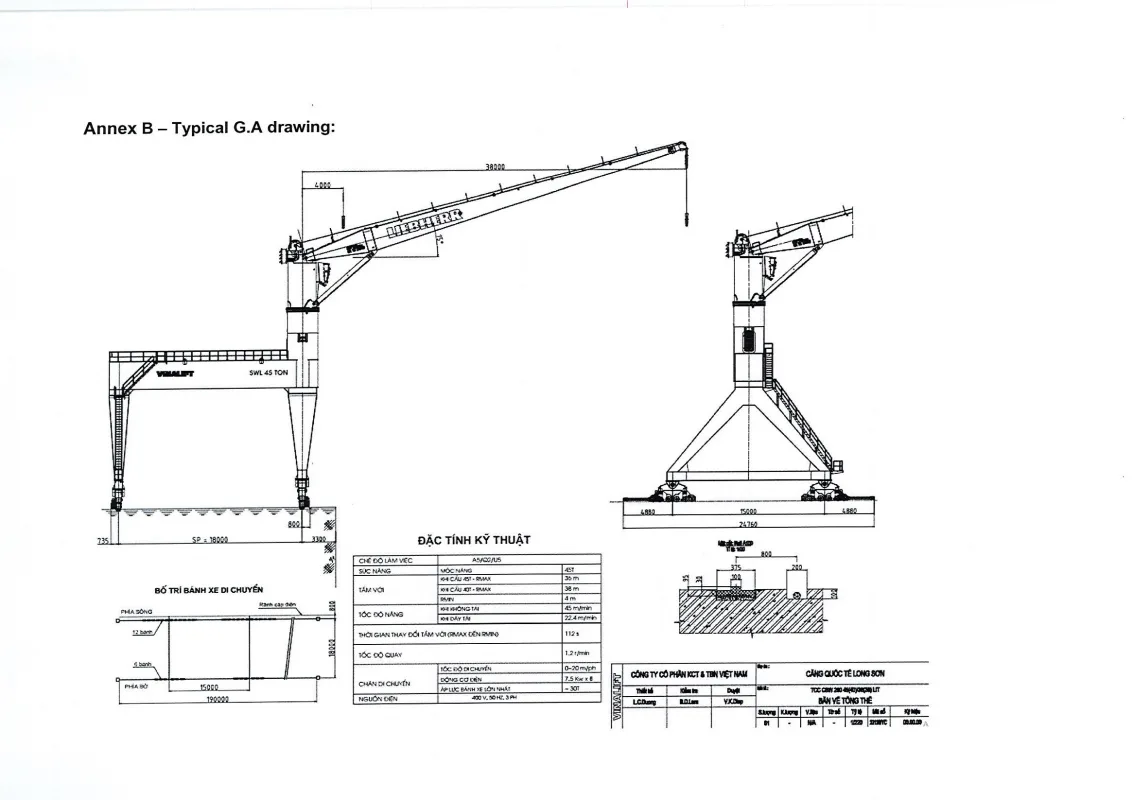

40 Ton Portal Crane | Long Son International Port

Safe lifting capacity at all radii:

– Using crane hook: 45 tons at 36m radius

– Using crane hook: 40 tons at 38m radius

Radii (measured from the center of the slewing axis):

– Maximum radius for hook operation: 38m

– Minimum radius during operation: 4m

Structure:

– Entire crane: Usage class U5

– Load class: Q2

– Classification group: A5

The two sets of TTC 280 Portal Crane manufactured by VINALIFT have been handed over to the investor of Long Son International Port. With years of experience and a strong reputation in the field of lifting equipment manufacturing, VINALIFT consistently provides customers with the best equipment, and the TTC 280 Portal Crane is one of those products. In this article, I will introduce detailed specifications of this crane for the port.

Technical Specifications for the 40-ton Portal Crane:

Design Conditions:

– Operating environment temperature: -20°C to +45°C

– Maximum humidity: 96%

– Calculated wind speed for the working boom: 20m/s

– Design standards: F.E.M 1.001 01.10.1987, QCVN 22:2010/BGTVT (National technical standards for the design and testing of handling equipment for transportation by the Ministry of Transport) for the mobile frame of the TTC 280 versatile crane.

Structure:

– Entire crane: Usage class U5

– Load class: Q2

– Classification group: A5

Stability:

The stability of the crane is designed in accordance with F.E.M 1.001 (latest version) and QCVN 22:2010/BGTVT (National technical standards for the design and testing of handling equipment for transportation by the Ministry of Transport).

Main Data for the 45T Portal Crane:

Safe lifting capacity at all radii:

– Using crane hook: 45 tons at 36m radius

– Using crane hook: 40 tons at 38m radius

Radii (measured from the center of the slewing axis):

– Maximum radius for hook operation: 38m

– Minimum radius during operation: 4m

Operating speeds:

– Hoisting/lowering speed at full load 45 tons: 0 to 20.5 m/min

– Hoisting/lowering speed at full load 40 tons: 0 to 23 m/min

– Hoisting/lowering speed at full load 30 tons: 0 to 29.5 m/min

– Hoisting/lowering speed unloaded: 0 to 40 m/min

– Slewing speed: 0 to 1.23 rpm

– Traveling speed of the pedestal: 0 to 20 m/min

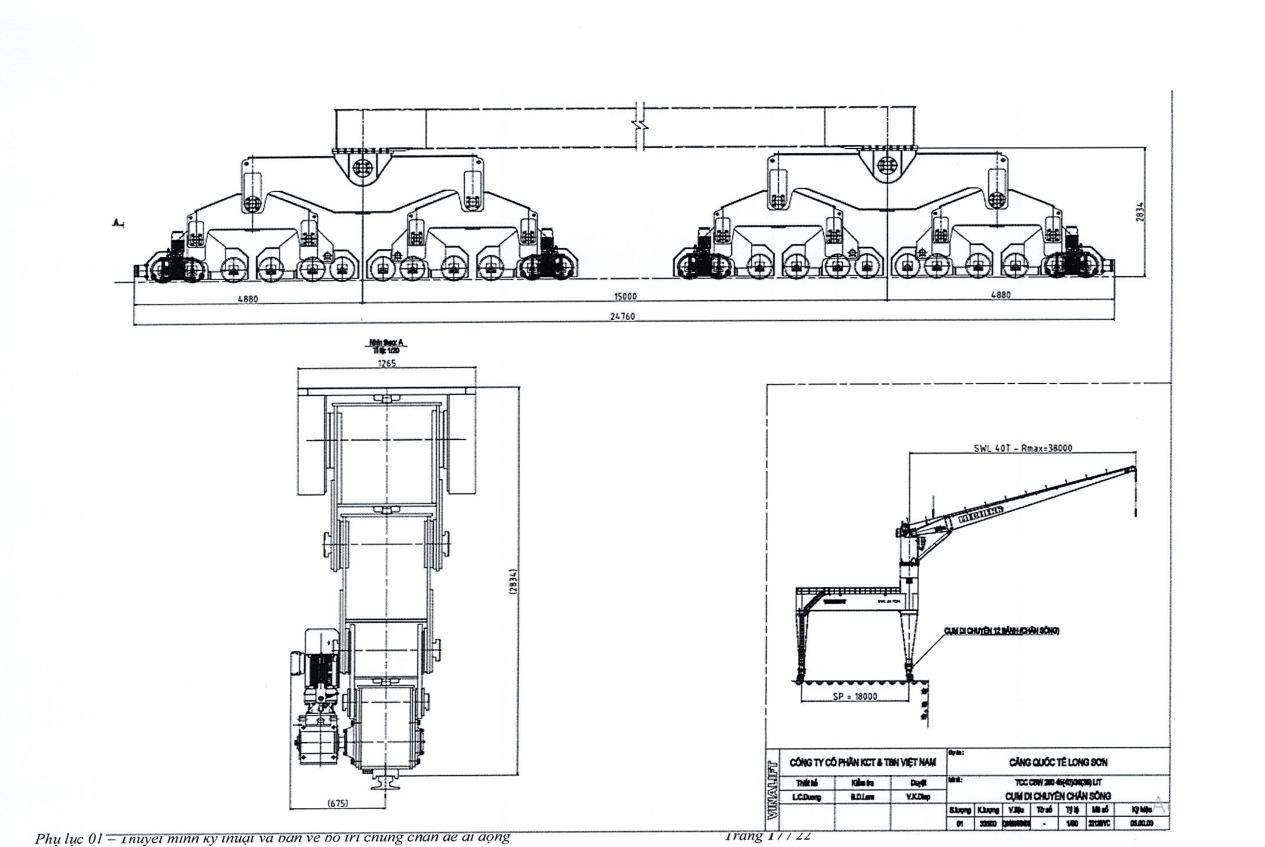

Rail gauge: 18m

Static height below the pedestal: 12m

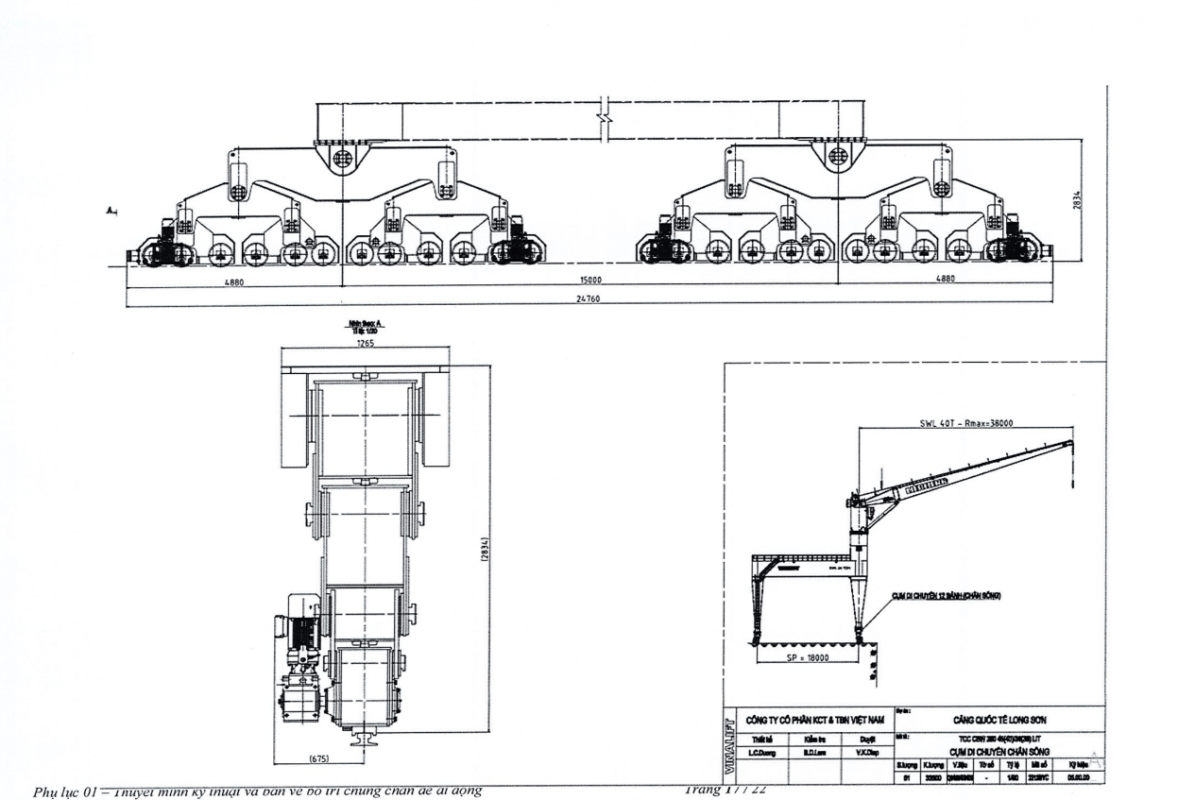

Distance between the two sets of feet along the longitudinal moving rail: 15m (Total moving width of the set 24.3m)

Pedestal height from the top of the rail to the slewing bearing: 20m

Total number of wheels: 36 pieces

Wheel diameter: 500 mm

Maximum wheel pressure: 30 tons

Length of the port movement: ~ 200m

Travel drive system:

– Motor power: 7.5 kW x 8 sets

– Power supply: AC 3-phase, 380V, 50Hz

– Enclosure rating: IP55

Power supply: 380V, 3-phase, 50Hz

Rail type: A100

Maximum noise of the entire pedestal during operation: < 85dB (within 6m from the noise source)

Brand new equipment, 100% unused

Crane certification: Safety inspection center

Power supply winding (Low voltage 380V)

Type: Double winding, connection joint from

Crane travel length: +/- 100m

Steel Structure:

This is the basic structure to support the TTC 280 crane pedestal and is considered the mobile pedestal system. The structure consists of welded box beams to ensure rigidity, stability, and easy inspection and maintenance. The pedestal part is made of steel with a yield strength of ≥235 N/mm², a tensile strength in the range of 373-480 N/mm², and a relative elongation of 24% or equivalent. Before welding, the welding procedure is certified and follows approved processes or drawings.

The steel structure consists of three parts: the main beam, pedestal, and pedestal beam described as follows:

Main Beam:

The main beam is designed in a box shape to ensure rigidity, good bending and torsional resistance, and lightweight. On the river side of the beam, a tube is welded with a thickness and diameter corresponding to the crane’s connecting tube (Adapter). This connecting tube goes into the main beam, connecting the upper plate and lower plate of the beam. The lower part of the beam is connected to the feet by welding.

Welding the pedestal to the crane connecting tube ensures concentricity and alignment of the crane’s connecting tube axis.

Pedestal Structure:

The pedestal has a box shape, and a triangular shape to ensure rigidity, compactness, and aesthetics. The pedestal includes the land-side foot part and the water-side foot part. The pedestal structure is assembled with the main beam. The main beam and pedestal are designed with crawl holes to allow workers to enter for structure inspection and maintenance.

Stairs, Handrails:

Stairs run along the land-side foot, wide enough to reach the top of the main beam, into the crane column, and up to the crane cabin. Additionally, access can be made inside the pedestal to inspect, and store equipment, and steel structures. The stairs have sturdy handrails. The top of the main beam is equipped with a safety handrail. The tubes used for handrails and handrails are galvanized steel tubes. The operating floor, walkway, stairs, and protective rails are hot-dip galvanized according to QCVN or equivalent.

The steel structure is supported by a system of wheel assemblies that can move on rails. The entire crane is supported on wheels, and installed in a system of multiple balance beams to ensure that the crane load is evenly distributed over all wheels. Electric motors provide the drive for the wheels to operate well in wind conditions of 20m/s.

Wheels, Axles, and Bearings:

Wheels are designed for A100 rails. The wheels are made of cast S45C, and the working surface hardness is 38~42HRC. The axles are made of S45C steel or equivalent. Friction-resistant bearings with lubricating grease are used. Wheels, wheel axles, and bearings are of the same size for easy replacement and assembly.

Drive System:

The drive system is a motor coupled to a gear reduction unit. The three-phase electric motor has high starting torque and stable operation, coupled with a sealed reduction unit lubricated with oil, ensuring high transmission efficiency. Each motor is equipped with electronic brakes. This brake system will automatically act when power is lost, ensuring safety when the boom needs to stop. The brake system will release automatically when power is restored.

This is an introduction to the detailed specifications of the VINALIFT-manufactured TTC 280 – 40-ton Portal Crane. If you want to learn more about this pedestal crane series, you can refer to the following articles:

SEE MORE: FLAT PORT PORTAL CRANE – HAI PHONG