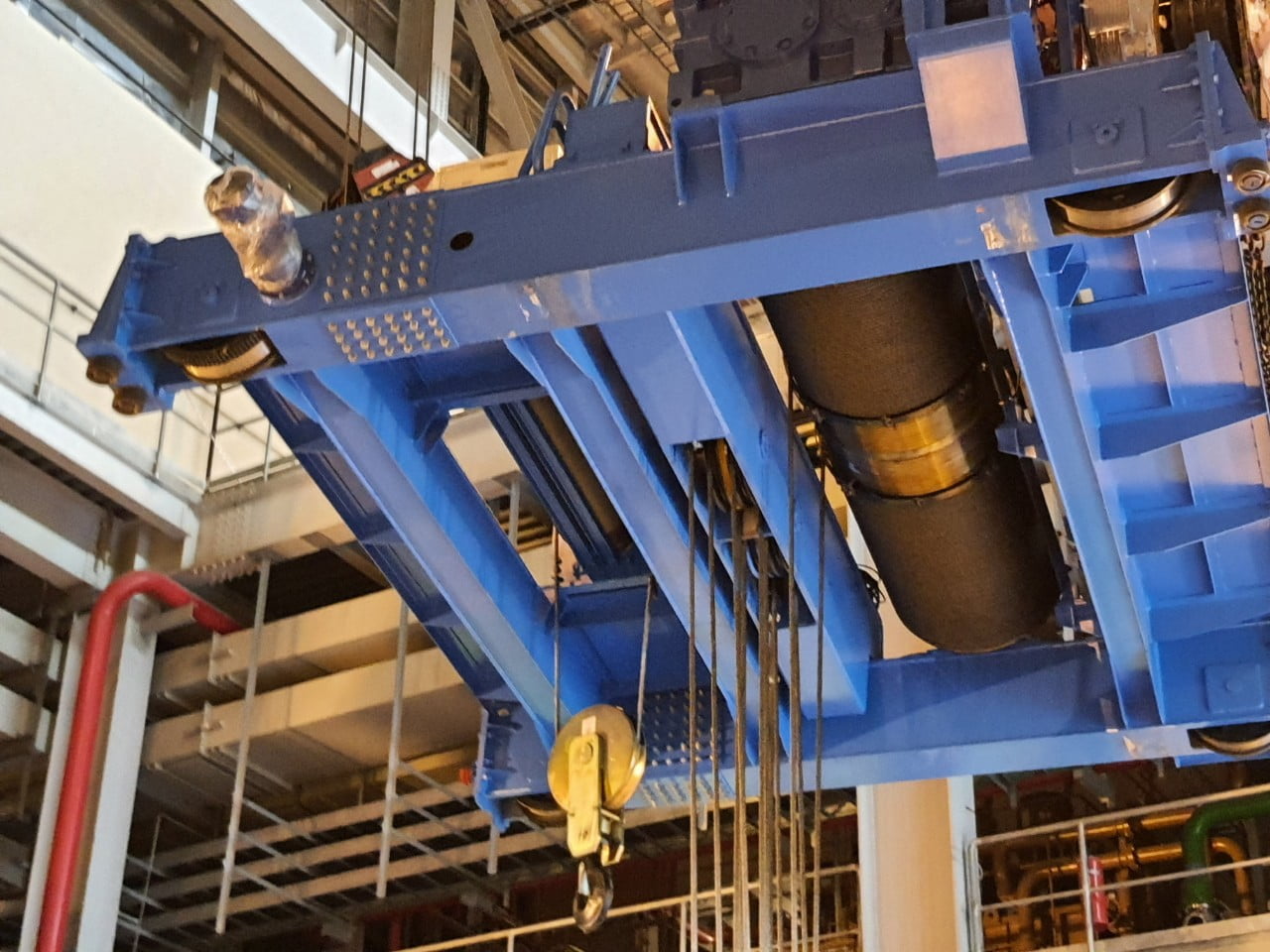

80-TON OVERHEAD CRANE

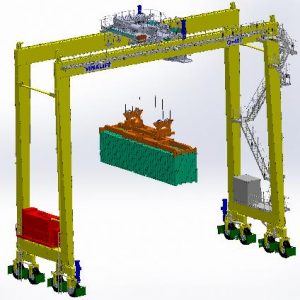

Crane Type: Double Girder Crane

Model: CaK 80/20T

Quantity: 01 set

Operating Mode: 1 Am to 5m

Lifting Capacity:

- Main Hook Load: 80 tons

- Auxiliary Hook Load: 20 tons

Crane Span: As per requirements

Main Hook Lifting Height: As per requirements

Auxiliary Hook Lifting Height: As per requirements

Overall Length: As per requirements

Technical Profile of 80-ton Overhead Crane

Applicable Standards

- Crane Manufacturing Standard: TCVN 4244-05 (Vietnam), FEM 1.001

- Structural Welding Standard: AWS D.1.1

- Coating and Surface Protection Standard: ISO 8501; SSPC – SP10

Technical Specifications: 80-ton Overhead Crane

Crane Type: Double Girder Crane

Model: CaK 80/20T

Quantity: 01 set

Operating Mode: 1 Am to 5m

Lifting Capacity:

- Main Hook Load: 80 tons

- Auxiliary Hook Load: 20 tons

Crane Span: As per requirements

Main Hook Lifting Height: As per requirements

Auxiliary Hook Lifting Height: As per requirements

Overall Length: As per requirements

Working Environment

Ambient Temperature: 0~45°C

Humidity: 98%

Speed

Main Hook Lifting Speed: 02.3 m/min

Auxiliary Hook Lifting Speed: 05 m/min

Cross Travel Speed: 020 m/min

Long Travel Speed: 030 m/min

80/20-ton Electric Hoist

Lifting Hoist 80 tons

Lifting Motor: 37 kW / 01 unit / SIEMENS

Lifting Gearbox: 01 unit / SUMITOMO

Lifting Brake: 02 units / South Korea

Wire Rope Drum: Q345B Steel Cable: D22mm / South Korea / Thailand

Pulley: S35C Steel

20-ton Electric Hoist

Lifting Motor: 30 kW / 01 unit / SIEMENS

Lifting Gearbox: 01 unit / SUMITOMO

Lifting Brake: 01 unit / South Korea

Wire Rope Drum: C20 Steel / China

Steel Cable: D22mm / South Korea / Thailand

Pulley: S35C Steel

Crane Trolley

Motor: 7 kW x 2 units / SUMITOMO

Brake: Electromagnetic Brake

Electrical Cabinet

Frequency Converter for Main Hook Control: 45 kW / Mitsubishi / 01 unit

Frequency Converter for Auxiliary Hook Control: 37 kW / Mitsubishi / 01 unit

Frequency Converter for Cross Travel Control: 5 kW / Mitsubishi / 01 unit

Frequency Converter for Long Travel Control: 30 kW / Mitsubishi / 01 unit

PLC Control: Mitsubishi / 01 unit

Safety Equipment

Main Hook Travel Limit

Auxiliary Hook Travel Limit

Overload Protection

Limiting the Travel of Trolley and Crane

Alarm Bell for Vertical Crane Movement

Collision Prevention for 02 Cranes

Steel Structure for 80-ton Crane

Beam Structure: Box Girder – Welded Connection

Material: Q235B/SS400/A36

Main Beam Stiffness: 1/850

Handrail, Working Platform:

- Non-Destructive Testing of Welds: According to AWS D1.1-2015 Standard

- Plate Weld Inspection: UT 100%

- Groove Weld Inspection: MT 20%

- Weld Inspection and Certification: PHATECO/ VIMISCO

80-ton Crane Travel Assembly

Wheel Diameter: D500mm

Material: S45C / Heat Treated 38~42HRC

Number of Wheels: 8 wheels

Crane Travel Power: 5 kW x 4 units

Brake Type: Electromagnetic Disc Brake

Origin: SUMITOMO

Electrical System

Power Supply:

- AC 380V, 3Phase, 50Hz

- Control Voltage for Crane: 48V

Crane Control: Enclosed Cabin and Remote Control

Power Supply for Trolley along the Main Beam: Deep Groove Cable Roller Type in I-beam channel, with a length of 23 meters.

Power Supply for Crane along the Runway: Existing power supply line.

Control Panel and Other Accessories: Complete installation of circuit breakers, contactors, roles, etc., by Schneider, Mitsubishi Vietnam, 01 set.

Cleaning and Painting:

- The entire steel structure was cleaned on a surface treatment line using shot blasting.

- Surface Cleaning: Sa 2.5 according to ISO8501 standard

- Painting Process: Epoxy paint, total paint thickness 200 microns according to SSPC – SP10 standard.

Thank you for reading this article. Please follow us on our WEBSITE or social media platforms such as FACEBOOK, LINKEDIN, and YOUTUBE for new articles with useful information.

READ MORE: 5-TON OVERHEAD CRANE