Gantry cranes are widely used for the mechanical handling of goods and materials in various industrial settings, including factories, warehouses, and ports. With their versatility, affordability, and suitable lifting capacities, 3-ton gantry cranes have become popular for businesses across diverse industries.

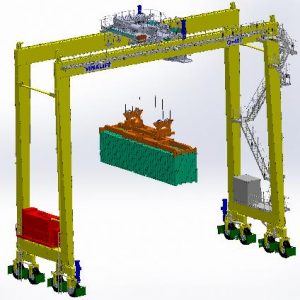

Detailed Structure of a 3-Ton Gantry Crane

Featuring a dual underhung rail design, the equipment can operate outside the workshop’s covered area at any location with all load capacities and ensures high stability. The 3-ton gantry crane can be classified into two main types: single-girder and double-girder cranes.

3-ton single girder gantry crane

- Main girder (single girder): I-beam or box girder assembly

- 3-ton hoist

- Gantry crane legs

- Gantry crane power supply system

- Edge girders and gantry crane drive system

3-ton double girder gantry crane

- Main girder (double girder): I-beam or box girder assembly

- 3-ton trolley hoist

- Gantry crane power supply system

- Edge girders and gantry crane drive system

Single or double-beam gantry crane structures are often equipped with stairs, railings, and floors to repair and maintain equipment.

Advantages

Flexible Lifting Capabilities: Small mobile gantry cranes with wheels can move flexibly over a wide range, easily lifting and lowering goods to any location within the workshop.

Suitable Lifting Capacity for Most Factories and Workshops: 3-ton gantry cranes can meet the lifting needs of various goods with different sizes and weights.

Efficient Operation: Saves time and labor in transporting goods, improving work efficiency.

Cost-Effective: Compared to large gantry cranes, small lifting capacity gantry cranes offer more options in terms of size and runway, which can significantly reduce costs.

Factors to Consider When Choosing a Gantry Crane

Determine usage requirements: Clearly define the purpose of use, lifting capacity, operating frequency, and working environment… to choose the appropriate type.

Choose a reputable supplier: It is recommended to purchase gantry cranes from reputable suppliers with many years of experience in gantry crane manufacturing and installation to ensure the best quality and after-sales service.

Carefully check the technical specifications: It is necessary to carefully check the technical specifications of the gantry crane such as lifting capacity, lifting height, and span… before buying to ensure that it meets the usage requirements.

Regular installation and maintenance: Regular maintenance is required to ensure safety and efficiency of use.

With diverse advantages and applications, the 3-ton gantry crane is the optimal choice for businesses in many industries.

Thank you for reading this article. Please follow us on our WEBSITE or social media platforms such as FACEBOOK, LINKEDIN, and YOUTUBE for new articles with useful information.

SEE MORE: VINALIFT GANTRY CRANE CATALOG

SEE MORE: VINALIFT CRANE CATALOG