Container Handling and Transshipment Equipment System

Equipment System Area

Container Handling Zone:

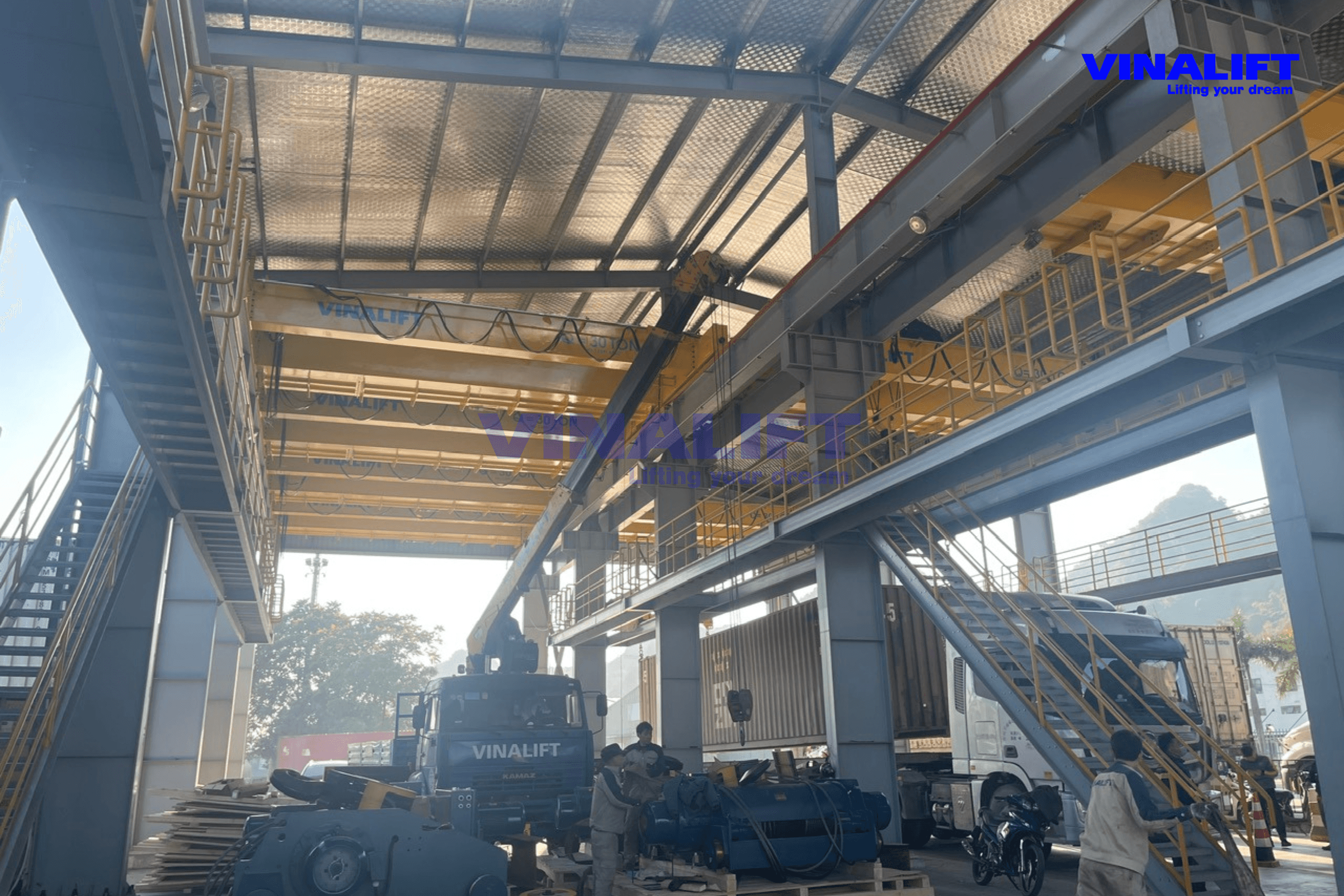

- Dimensions: 45m (length) x 20m (width).

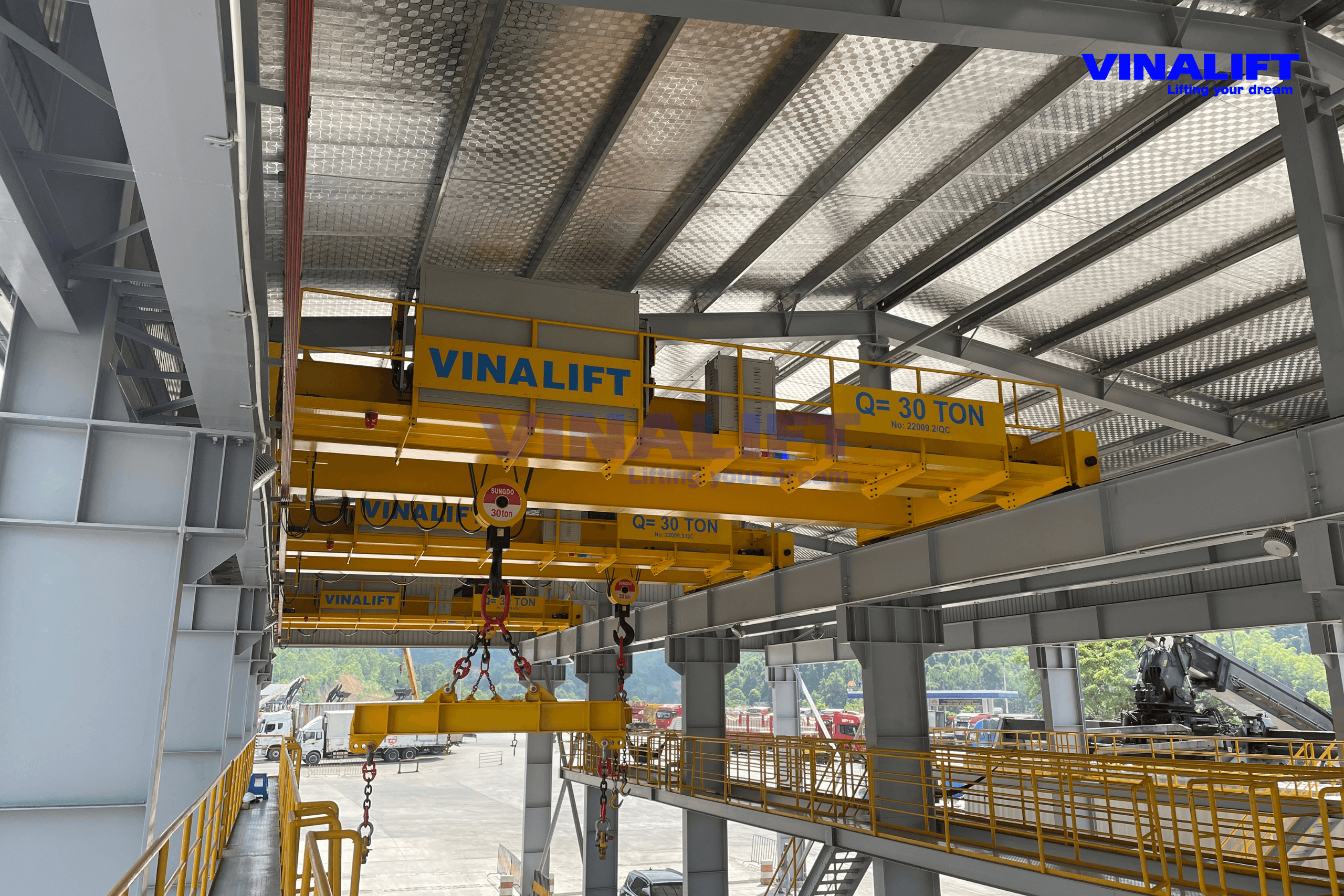

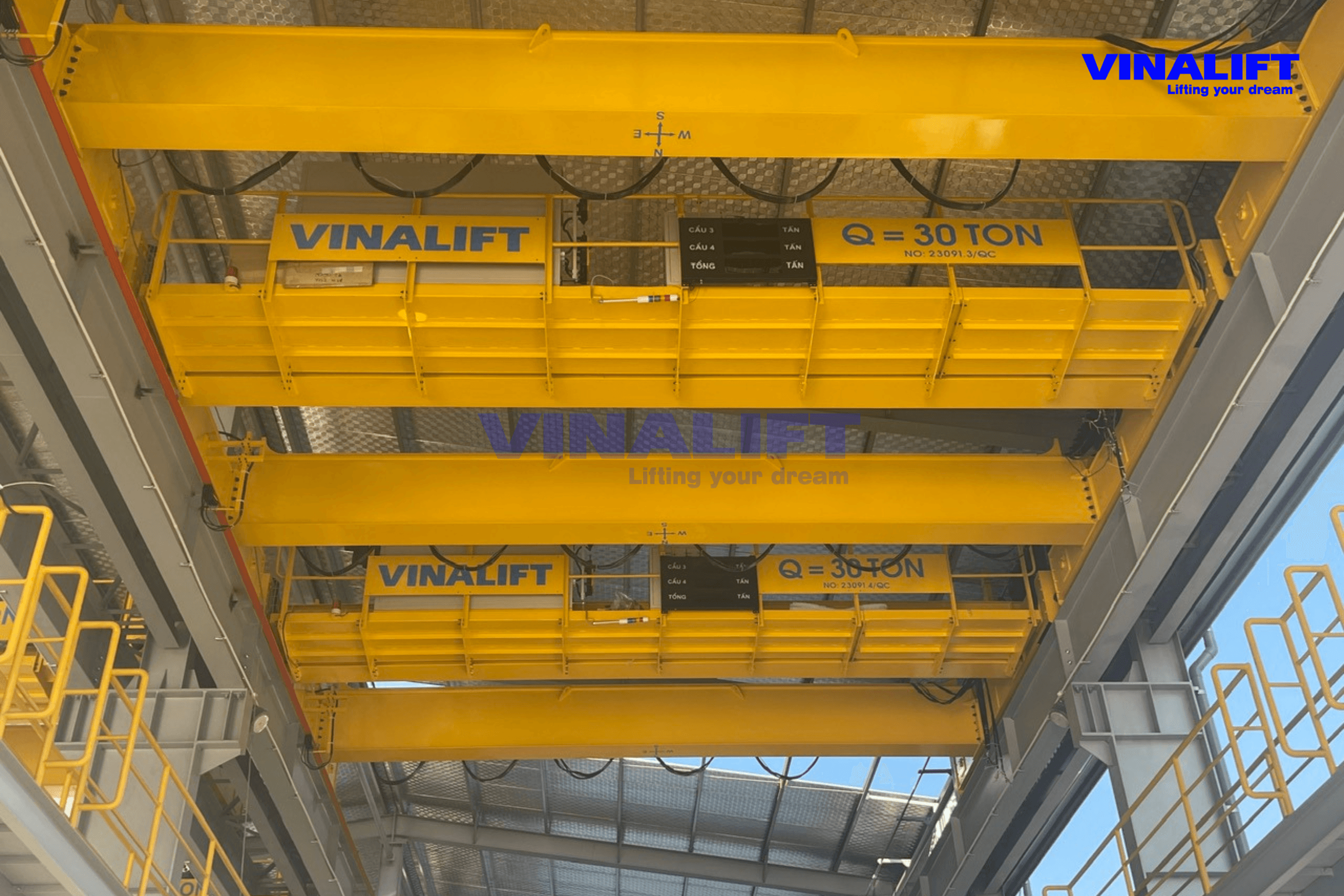

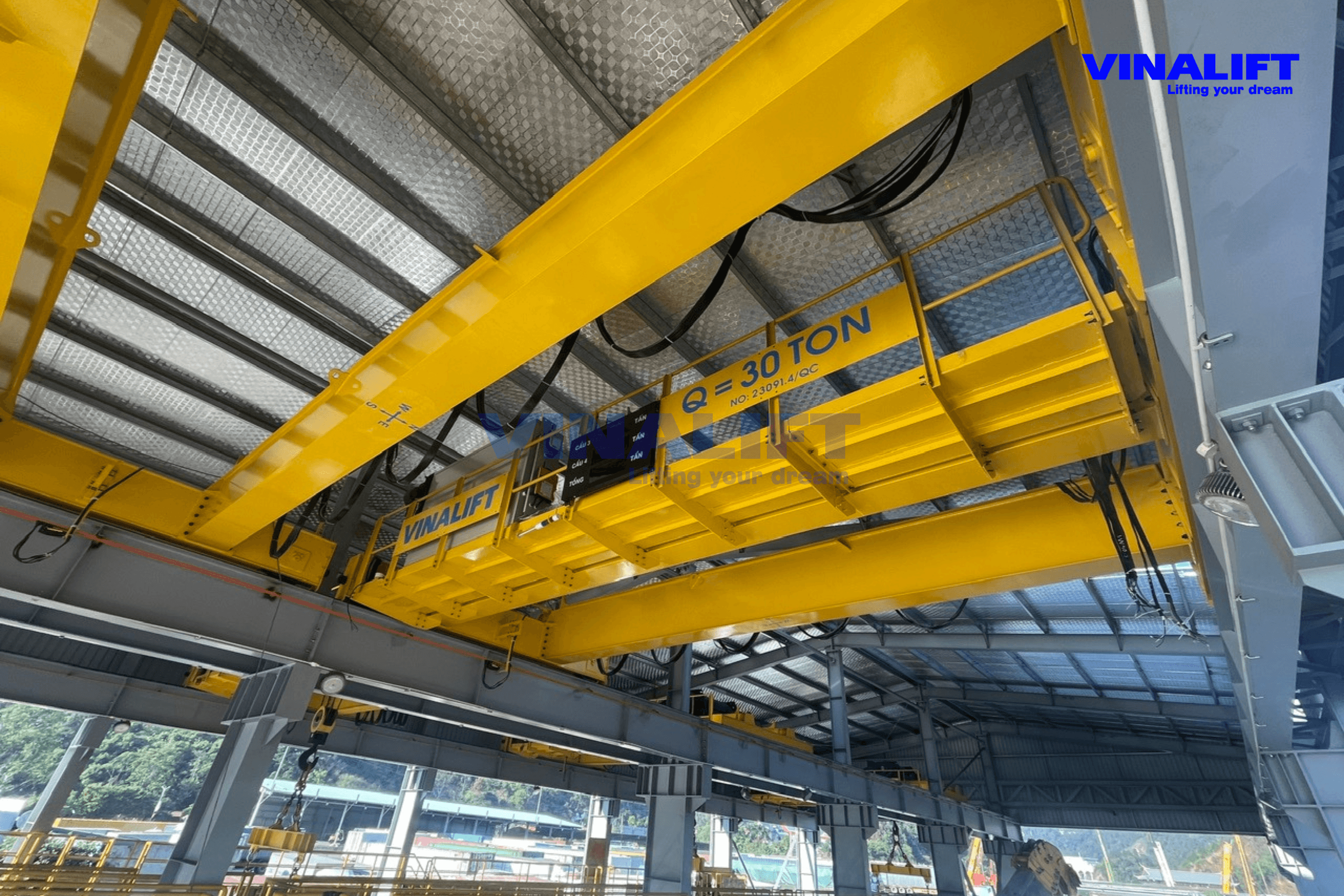

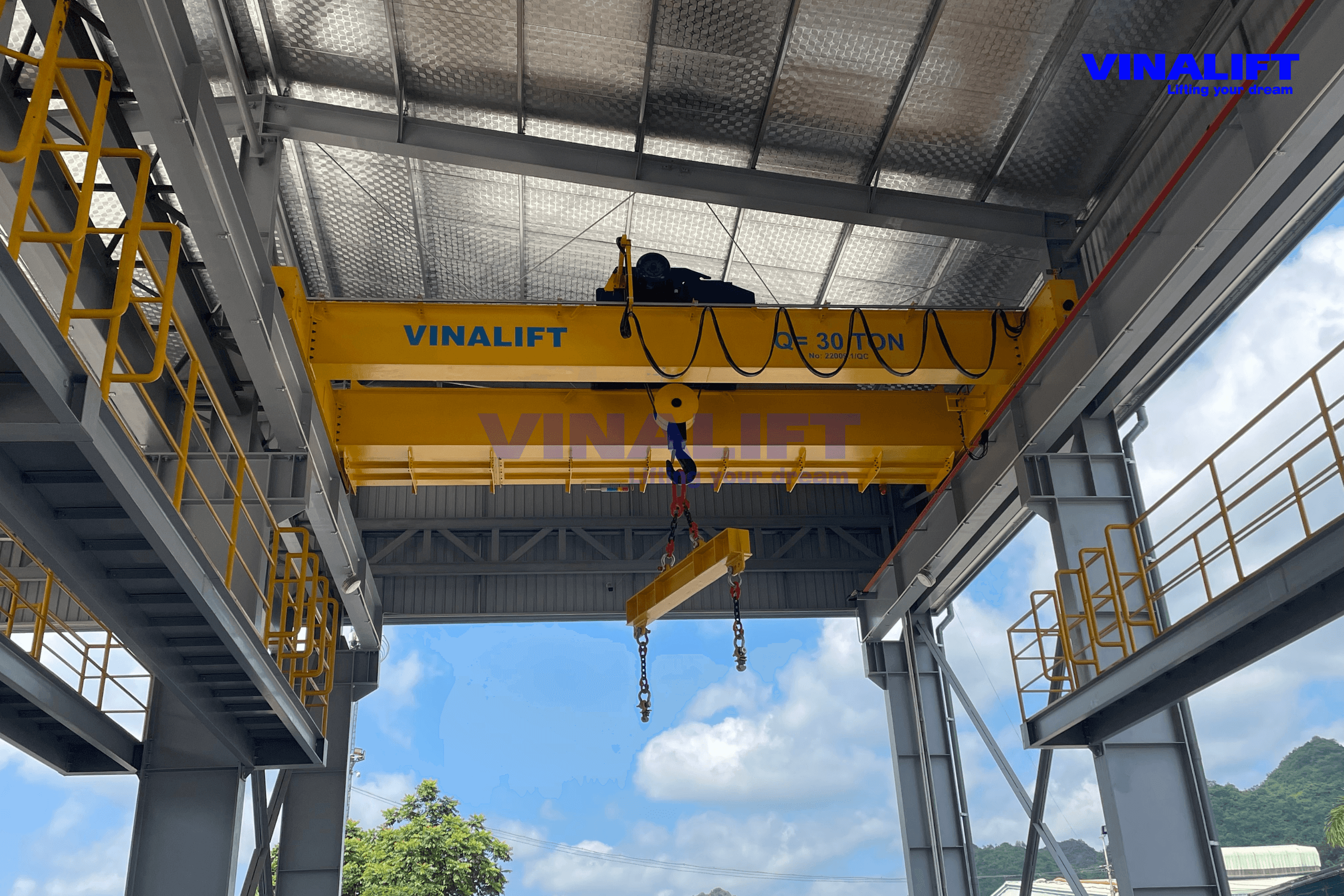

- Includes 2 buildings, each equipped with 4 lifting devices with a capacity of 30 tons.

Load Combination Calculations

- Maximum Container Weight Including Goods: 35 tons

- Maximum Empty Container Weight: 6 tons

- Maximum Weight of Container Lifting Beam: 2 tons/pair

Container Handling and Transshipment Equipment System

The Huu Nghi International Border Gate, located in Lang Son Province, Vietnam, is a key international gateway on the Vietnam-China border. It connects the Nanning-Hanoi Expressway as a crucial bridge for economic relations between Vietnam and China.

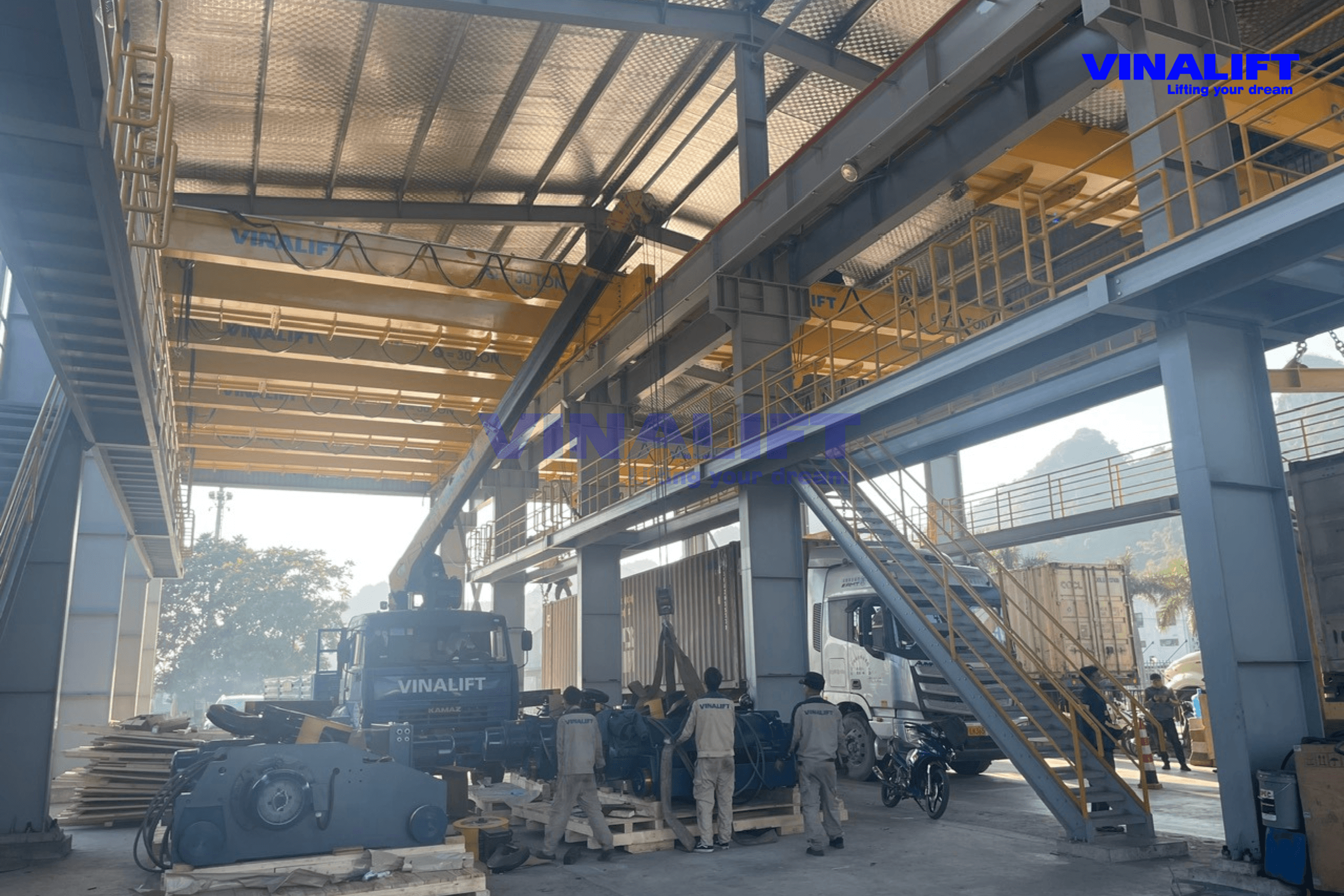

In response to the urgent need for transshipment between trucks transporting goods from Vietnam to China and vice versa, VINALIFT has developed and introduced an optimal container handling and transshipment equipment system. This system maximizes operational efficiency while minimizing customer costs.

Operation Plan

>>> See more: VINALIFT Gantry Cranes from 2 tons to 100 tons

Equipment System Area

Container Handling Zone:

- Dimensions: 45m (length) x 20m (width).

- Includes 2 buildings, each equipped with 4 lifting devices with a capacity of 30 tons.

Load Combination Calculations

- Maximum Container Weight Including Goods: 35 tons

- Maximum Empty Container Weight: 6 tons

- Maximum Weight of Container Lifting Beam: 2 tons/pair

Lifting Load Combinations

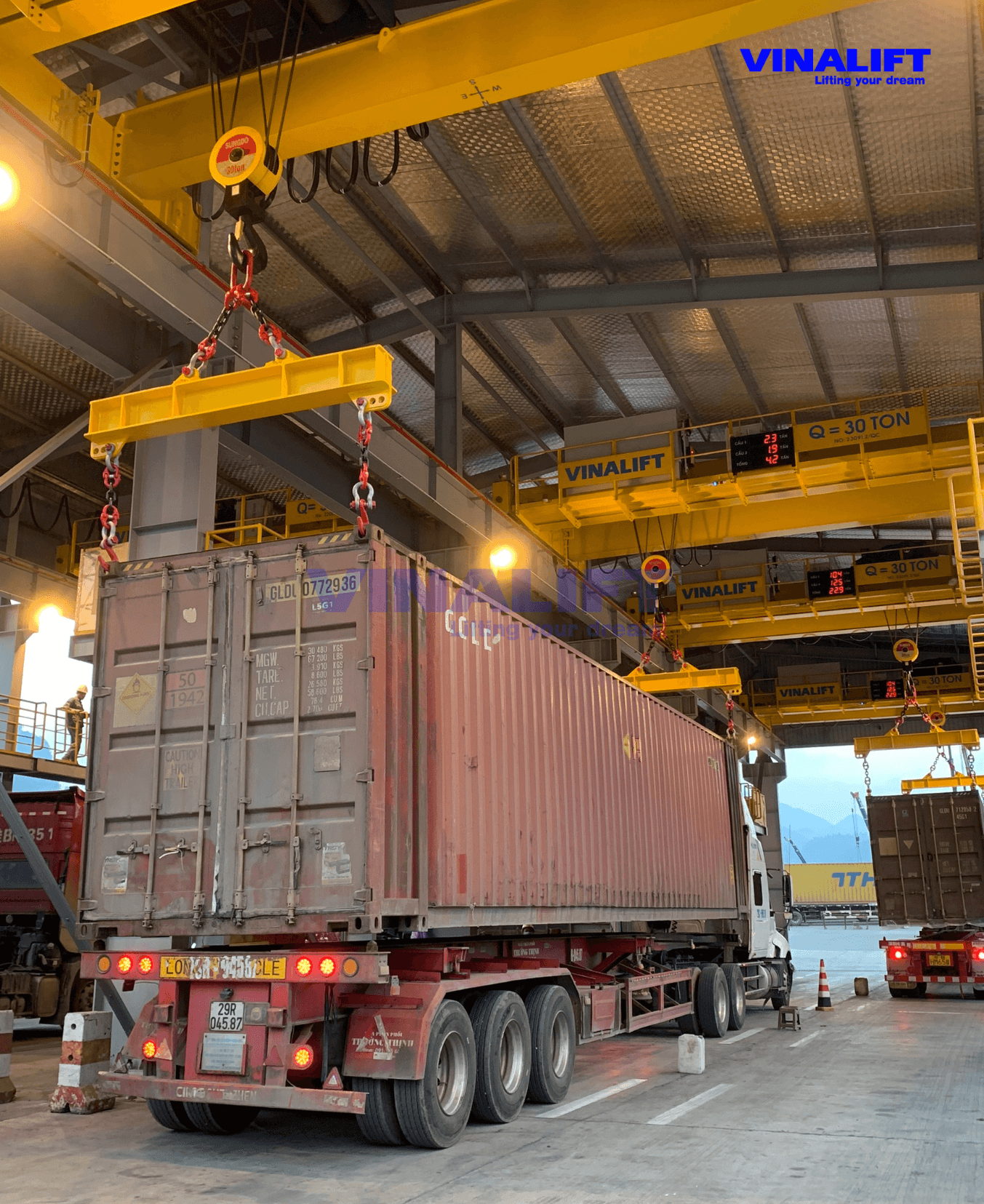

Loaded Containers:

- Total weight: 37 tons (including lifting beam).

- Uses two lifting hooks, each with a 30-ton capacity (total lifting capacity of 60 tons) to ensure safety in cases of uneven load distribution.

Empty Containers:

- Total weight: 8 tons (including lifting beam).

- Uses two lifting hooks, each with a 30-ton capacity (total lifting capacity of 60 tons) to ensure safe operation.

The lifting devices for both loaded and empty containers are the same, allowing seamless container entry into the handling area without prior classification.

Operational Speeds

Loaded Container Handling Assembly

- Lifting/Lowering Speed: 2.3 m/min / Precision approach: 1 m/min

- Horizontal Movement Speed: 12.5 m/min / Precision approach: 4 m/min

- Longitudinal Movement Speed: 10 m/min / Precision approach: 4 m/min

Empty Container Handling Assembly

- Lifting/Lowering Speed: 2.3 m/min / Precision approach: 1 m/min

- Horizontal Movement Speed: 12.5 m/min / Precision approach: 4 m/min

- Longitudinal Movement Speed: 10 m/min / Precision approach: 4 m/min

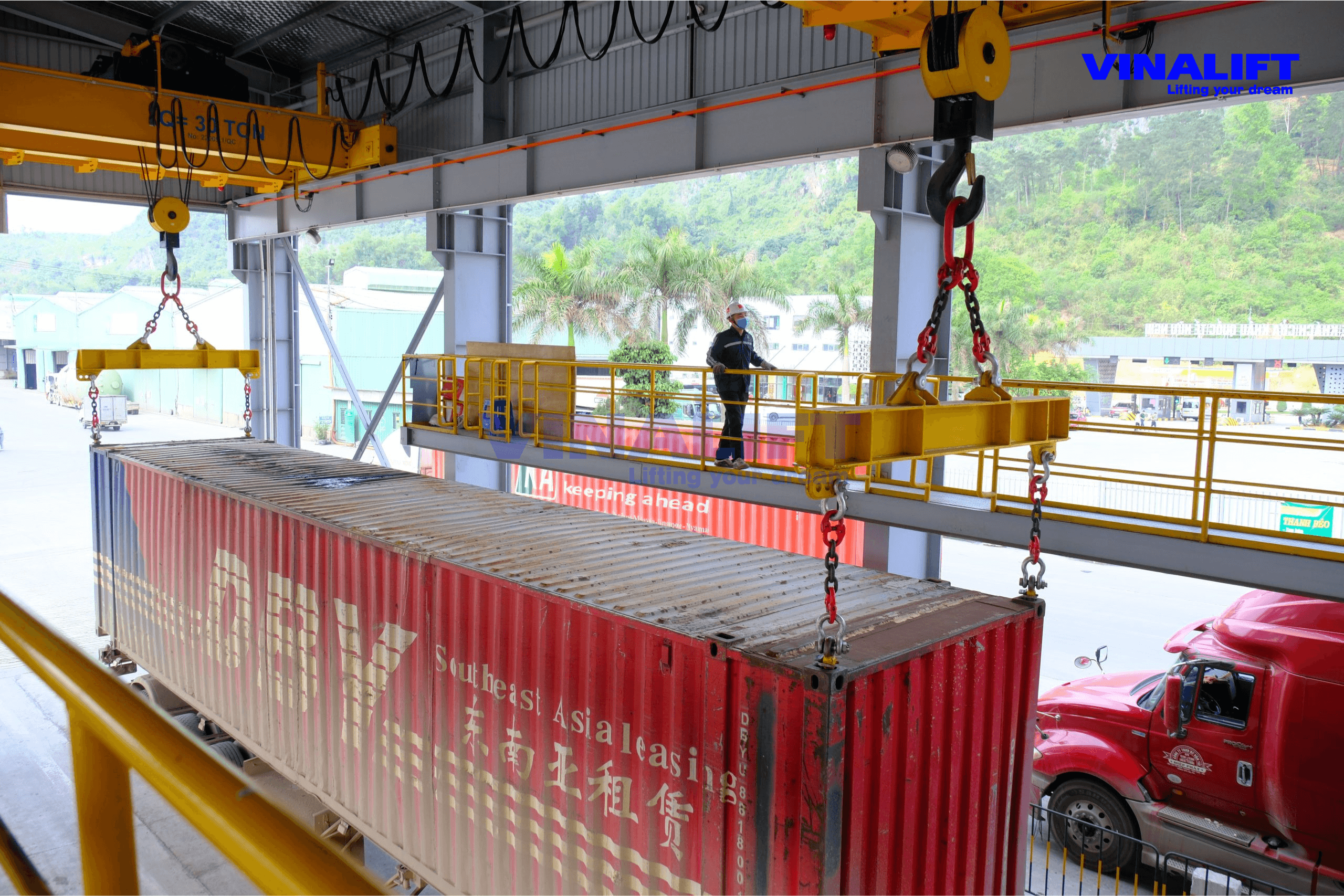

Lifting Beams

The lifting beams for both loaded and empty containers are designed identically for interchangeable use:

- Each 30-ton hook is equipped with a 2.3m-wide lifting beam. Chains and container locking cones are attached to the lifting beams for connection at suspension points (selection of locking cone or hook type depends on the investor’s preference).

- Bulk Material Handling: the lifting beams can be removed, and the hooks (each with a capacity of 30 tons) used directly. Maximum bulk material capacity: 120 tons

Note: The proposed solution addresses several practical issues:

- Uneven Parking Areas (Sloped Surfaces): The lifting beams are independently suspended on each lifting hook, allowing adjustment of individual hook heights to ensure balance during operation.

- Diagonal Parking of Trucks: The spacing between the two lifting hooks can be adjusted both longitudinally and laterally within the building, accommodating vehicles parked at an angle.

- The system is capable of handling containers with lengths ranging from 5m to 18m by flexibly and quickly adjusting the spacing between the two lifting hooks along the building’s longitudinal axis.

- Efficient Operation with Off-Centered Container Loads: Each hook can bear loads of up to 30 tons, ensuring safe and effective handling even when container loads are unevenly distributed.

- Alignment of Lifting Chains with Container Suspension Points: The lifting chains align directly with the container’s lifting lugs, eliminating the need for workers to manually carry chains. Workers only need to attach the locking cones or hooks. This design significantly improves labor productivity, particularly in high-intensity continuous operations.

Operational Workflow and Performance

Workflow

- Step 1: Move trucks from the waiting area to the container handling area.

| No. | Stage |

Implementation |

Time | Note |

| 1 | Move trucks from the waiting area to the container handling area. |

Distance: 40m

Guided by personnel for precise positioning |

80s | Draw a line on the floor to determine the location |

- Step 2: Perform container transshipment:

| TT | Stage | Implementation | Time | Note |

| 1 | Attach chains to the container | 02 workers move from the waiting floor to the top of the container, each holding 2 humps to put in the container and turn the latch. | 30s | Do 2 positions at the same time |

| 2 | Lift container vertically | The operator presses the vertical lift | 10s | 30cm above the truck bed |

| 3 | Move the vehicle from position 2 to position 2-2 |

Drive straight 20m.

Workers move across the floor to 2-2

|

40s | |

| 4 | Move the crane from position 1 to position 2-2 |

Travel distance: 5m

Workers move to the roof of the Cont

|

20s | |

| 5 | Lower the empty container onto the car and move away from the location | Put Cont on the bike and remove the hunchback. Workers move up the railing to position number 2 | 40s | This operation is performed simultaneously |

| 6 | Reverse the car from position 1 to position 1-1 |

Driver reverses 20m.

Workers move across the floor to 1-1

|

60s | |

| 7 | Move the crane from position 2 to position 1-1 |

Travel distance: 5m

Workers move to the roof of the Cont

|

20s | |

| 8 | Lower the cargo container onto the car and move from the location |

Lower the Container onto the vehicle, remove the hump.

Workers move up the railing to position 1

|

40s | |

| Total Execution Time | 220s |

Mining productivity

Total Execution Time per Cycle: 5 minutes (300 seconds).

- 12 cycles/hour

- 96 cycles/day (8 working hours) per building.

Manpower Requirements

- Chain Hook Operators: 2 per position → Total: 4 personnel.

- Crane Operators: 1 per position → Total: 2 personnel.

- Qualifications: Skilled labor trained in occupational safety.

Control and Basic Technical Specifications

Control System

Anti-sway technology ensures stable operation and precise control.

Variable frequency drive (VFD) for seamless speed adjustments.

- Mode 1: Both hoists operate simultaneously.

- Mode 2: Operate Hoist 1 only.

- Mode 3: Operate Hoist 2 only.

— Backup Control: Handheld push-button control for emergency use with identical operational modes.

- Mode 1: Both hoists operate simultaneously.

- Mode 2: Operate Hoist 1 only.

- Mode 3: Operate Hoist 2 only.

Basic Technical Specifications

Loaded Container Lifting Equipment

Model: CaK30+30 x 8M

Lifting Capacity: 35 tons

Hook Capacity: 2 x 30 tons per hook

Hook Height: 7.7m

Building Length: 45m

- Lifting speed: 2.3/ 1 m/min

- Transfer speed: 12.5/ 4 m/min

- Road speed: 10/ 4 m/min

Total Power Consumption: ~ 46 kw

Empty Container Lifting Equipment

Model: CaK30+30 x 8M

Lifting Capacity: 35 tons

Hook Capacity: 2 x 30 tons per hook

Hook Height: 7.7m

Building Length: 45m

- Lifting speed: 2.3/ 1 m/min

- Transfer speed: 12.5/ 4 m/min

- Road speed: 10/ 4 m/min

Total Power Consumption: ~ 46 kw

Container Lifting Beam, Empty Container

Thank you for reading this article. Please follow us on our WEBSITE or social media platforms such as FACEBOOK, TIKTOK LINKEDIN, and YOUTUBE for new articles with useful information.