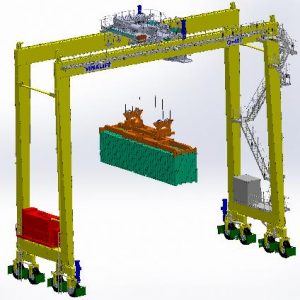

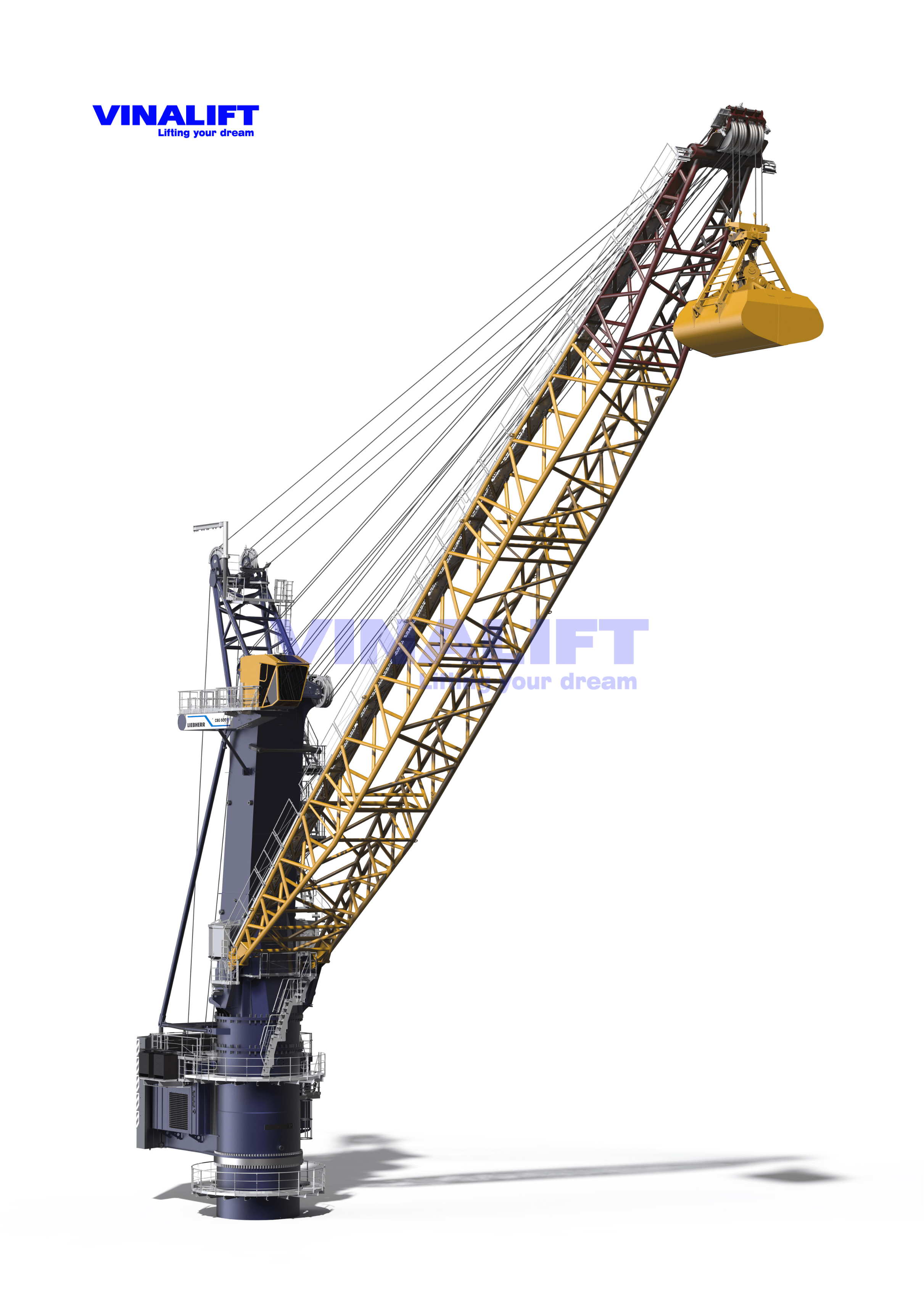

105 Ton Crane – CBG 500 E

The current trend in ports is to accommodate larger and heavier cargo ships. This necessitates an increase in ports’ loading and unloading capacity to expedite vessel turnaround and facilitate the flow of goods.

Following this prevailing tendency, VINALIFT provides customer equipment that meets the current industry requirements.

Technical data

Maximum lifting capacity:

- 105T (Hook operation)

- 90T (Grab operation)

Maximum outreach: 50m

Ship size:

- Container vessel: Post Panamax

- Bulk cargo vessel: VLBC, Cape Size

Speeds:

Hoisting/lowering (SWL on the rope)

- Maximum hoisting/lowering up to 32t SWL: 0 m/min – 140 m/min

- Maximum hoisting/lowering with 50t SWL: 0 m/min – 110 m/min

- Maximum hoisting/lowering with 65t SWL: 0 m/min – 85 m/min

- Maximum hoisting/lowering with 75t SWL: 0 m/min – 74 m/min

- Maximum hoisting/lowering with 90t SWL: 0 m/min – 61 m/min

- Maximum hoisting/lowering with 105t SWL: 0 m/min – 53 m/min

Slewing

- Speed: 0 rpm – 1.6 rpm

- Range: 360° unlimited

Luffing

- Maximum luffing: 0 – 85 m/min

Design conditions

Maximum admissible

- Heel/trim: 5°/2° or 2°/5°

- Design temperature: -10°C

- Ambient working temperature: -20°C to + 45°C

Maximum wind speed

- Working condition: 20 m/sec (0.245 kN/m²)

- Parking condition: 63 m/sec

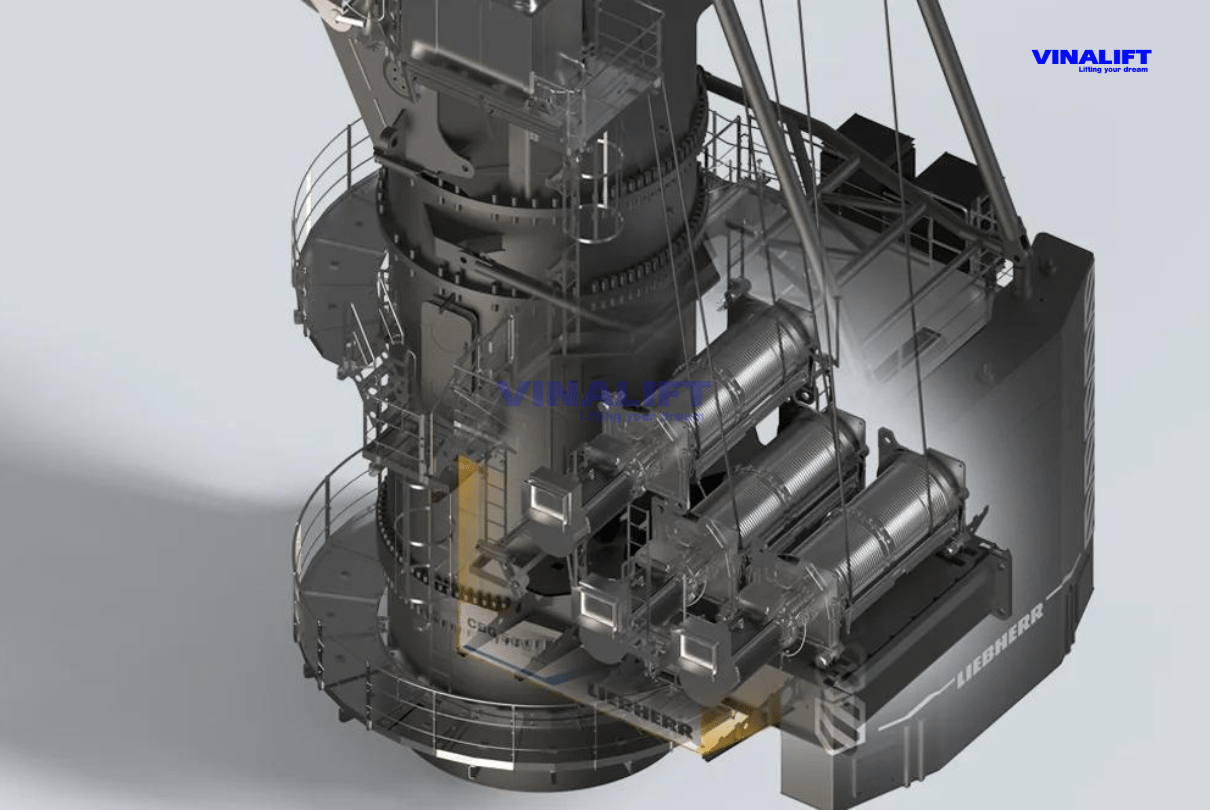

Electric motor

Type of motor: Three-phase squirrel cage

Class of insulation: F

Starting: Inverter

Main power supply (standard): 690V, 3ph

Auxiliary power supply (standard): 440V, 3ph+N

Crane classification

The maximum group classification according to FEM 1.001 (last edition) of the CBG crane relates to full load cycles in grab operation and is as follows:

< 65t

Crane as a whole: A8 /Q3 /U7

Optional features

Spacious 10 m³ cabin.

Comfort ascent to crane driver’s cabin.

increased stability and load charts with a counterweight.

Additional platforms and boom walkways for service and maintenance purposes.

Intelligent automatic greasing systems.

Camera systems for different areas of the crane.

Complementary service devices.

Operational flexibility for special lifting equipment by the installation of electrical cable drum

Advantages

All-electric driven crane

Ergonomic driver’s seat and control layout

simplified maintenance of electrical components

Energy-efficient system due to energy recovery system

Closed water cooling system for power electronics

Fulfillment of customer-specific requirements through a variety of crane configurations and options

Thank you for reading this article. Please follow us on our WEBSITE or social media platforms such as FACEBOOK, LINKEDIN, and YOUTUBE for new articles with useful information.

=>>> READ MORE: CBG 360 – 45 TON