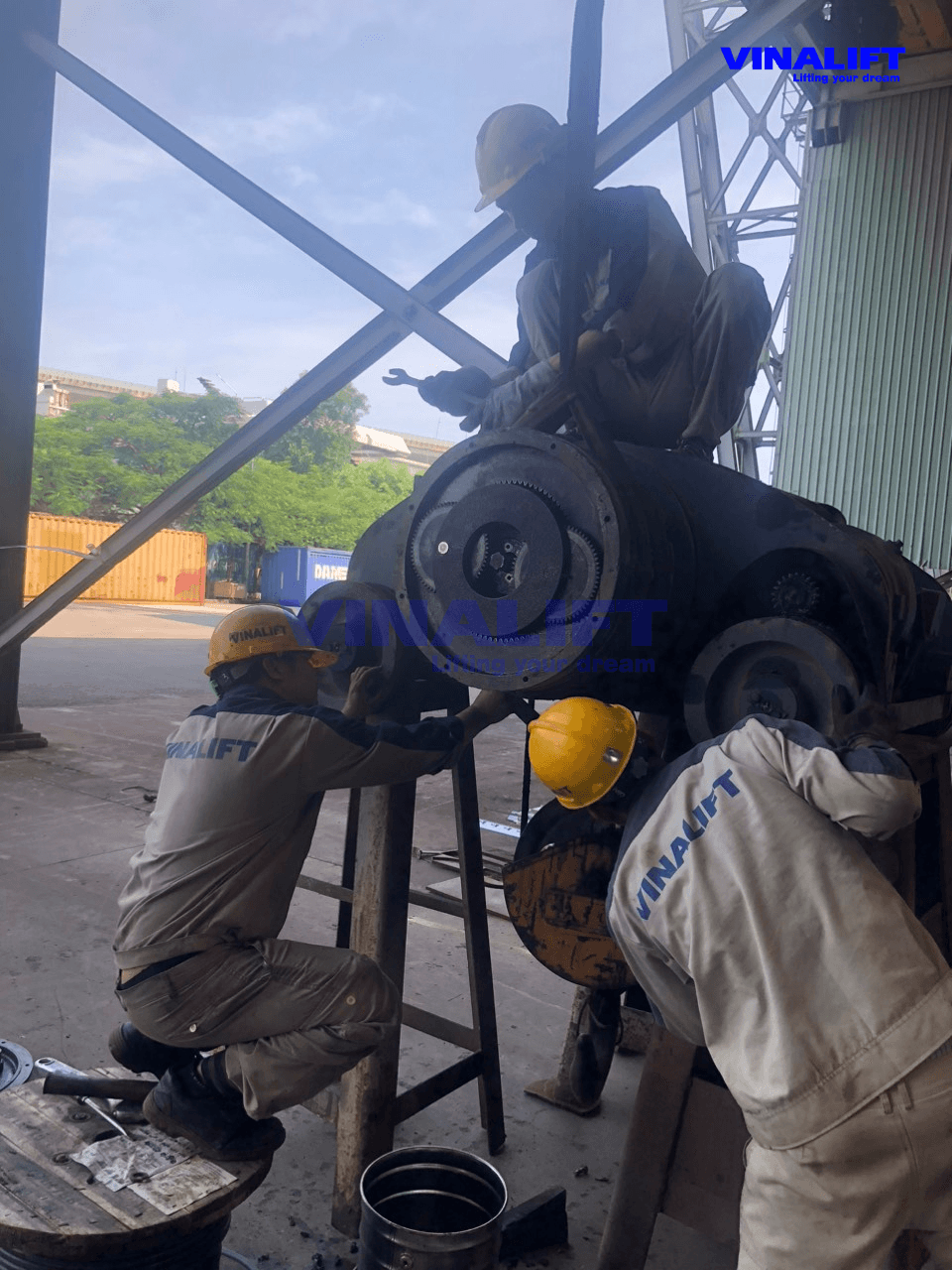

OVERHEAD CRANE REPAIR AND MAINTENANCE SERVICES

VINALIFT offers comprehensive 24/7 overhead crane repair and maintenance services

Cranes are indispensable lifting equipment in factories and workshops, significantly benefiting businesses across various industries. Given their critical role, regular overhead crane repair and maintenance services are essential to extend their lifespan and ensure safe, smooth operation.

What is overhead crane inspection and maintenance?

Overhead Crane maintenance involves a thorough inspection to objectively assess the crane’s condition and develop a plan to address any issues affecting its operation and safety after prolonged use.

With a skilled workforce and an optimized maintenance process honed over nearly 20 years, VINALIFT is ready to provide overhead crane maintenance services to customers throughout North, Central, and South Vietnam in the shortest possible time.

When should a crane be serviced?

Like other industrial equipment, crane components will gradually deteriorate over time. Regular inspections are necessary to detect any anomalies promptly and perform timely repairs and maintenance to prevent accidents.

Typically, after the warranty period, components such as lifting cables, brake pads, and crane power supply systems will experience natural wear and tear during operation. Therefore, inspection and maintenance are crucial tasks that must be performed comprehensively.

=> See more: Overhead Crane Maintenance progress

What does a crane maintenance package include?

Step 1: Comprehensive inspection of the crane system:

- Inspect brake pad wear

- Inspect the hoist motor, travel motor

- Inspect lifting and lowering sensors

- Inspect horizontal and vertical travel limit switches

- Inspect the crane’s entire electrical system

- Inspect the quality of the hoist lubricant

- Inspect the control system

- Inspect the quality of the cable

- …

Step 2: Develop a suitable maintenance, repair, and replacement plan to avoid affecting the productivity and operations of the factory or workshop.

Step 3: Conduct acceptance testing and handover of the equipment.

Read more: Safe and Efficient Crane Operation Procedure

Read more: 8 Hand Signals for Crane and Hoist Operation

Thank you for reading this article. Please follow us on our WEBSITE or social media platforms such as FACEBOOK, LINKEDIN, and YOUTUBE for new articles with useful information.