CBG 360 | 50-Ton Crane, 36m Reach | Liebherr – VINALIFT

The current trend in ports is to accommodate larger and heavier cargo ships. This necessitates an increase in the loading and unloading capacity of ports to expedite vessel turnaround and facilitate the flow of goods.

In line with this general trend, VINALIFT offers customer equipment that aligns with the current industry needs.

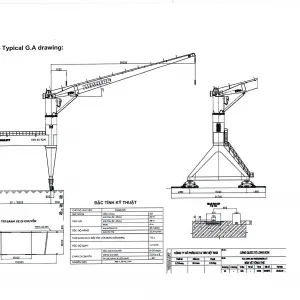

CBG 360 Shore Crane

The CBG 360 – 50-ton Liebherr crane is the most suitable product for ports receiving ships up to 100,000 DWT.

Equipment Origin:

CBG 360 portal crane consists of two parts:

- The base: Manufactured domestically by VINALIFT.

- The crane part: Manufactured by Liebherr – Federal Republic of Germany.

Boom structure

- Produced by Liebherr in Germany, Austria, and the United Kingdom

- High Capacity

- High strength

- The long service life of steel and components

- Classified as FEM U7/A8/Q3, the highest in marine cranes, equivalent to mobile quay cranes and ship-to-shore cranes

- Some specific components of the boom structure include:

- Boom structure: Germany/UK

- Hydraulic components: EU/Germany

- Ball bearing: Germany

- Control system: Germany/Austria

- Lifting cylinder: Germany/Austria

Crane Base:

- Designed according to FEM 1001 standards, tested, and approved by Vietnam Register.

- The steel structure of the crane base and moving assembly were produced at the VINALIFT factory.

- Control, transmission components, and power supply are imported from Japan, Europe, and the USA.

Technical Specifications of CBG 360 Crane:

- Lifting Capacity: 50 tons with a hook at a reach of 36m.

- Lifting Capacity: 45 tons with a grab at a reach of 38m.

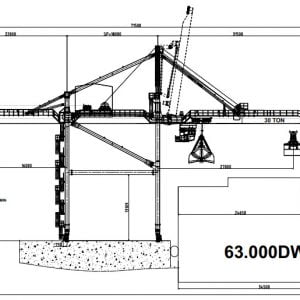

- Suitable for unloading 100,000 DWT bulk carriers.

- Suitable for unloading 50,000 DWT container ships (13 container rows).

- Front-end reach from the rail: 36m.

- Unloading capacity: 1000 tons/hour or 35 containers/hour.

- Loading speed: 39m/minute with a 50-ton load.

- Empty hook lifting speed: 108m/minute.

- Reach adjustment: 65 seconds.

- Operational intensity: 24/7.

- Effective rail span: 18~24m.

Ship size and handling capacity.

- CBG 360 gantry crane can handle ships up to 100,000 dwt and container ships up to 50,000 dwt (13 rows of containers).

- Handling capacity: 1000 tons/hour with bulk cargo

- Handling capacity: 32 containers/hour with container ships

Features of CBG 360 Crane:

- Cable-operated boom lifting, suitable for high-intensity operations

- A more advanced design than cable-operated boom lifting for high-intensity gantry cranes

- Extended cabin for optimal visibility

- Allows the crane operator to see deeper into the cargo hold instead of having to observe through a camera, thereby increasing handling speed.

Winch:

- Two hoisting winches placed outside the gantry crane allow the use of larger diameter hoisting drums to increase the service life of the cable (up to 4,000-6,000 hours, twice to three times that of smaller hoisting winches placed inside the crane)

- Allows for more cable to be wound, creating a larger lifting depth, suitable for ships up to 100,000 dwt

- Single-layer type, equipped with two mechanical and electronic cable slackening devices, no need to cut and move the cable regularly

- Large maintenance space, easy to check and monitor maintenance

- Very high durability, with a design life equal to the crane life, as has been proven in practice.

Boom

- Double boom

- Equipped with additional cross bracing to resist lateral and torsional forces when handling cargo, helping to reduce the weight and inertia of the boom rotation but still ensuring high durability, a design that has been patented.

- Made of high-strength steel in Germany/Austria/UK

- Held in place by two tail boom pins and two cylinder pins, completely eliminating shaking when handling cargo, locating the hook or bucket faster, helping to increase overall productivity by ~10%.

Litronic control system

- Military-standard electronic system.

- Withstands high temperatures up to 80 degrees Celsius without air conditioning.

- Resistant to strong vibrations up to 30g.

- Lightning protection casing for harsh environments.

- Currently used in the aircraft passenger living environment control system.

Crane Base:

- Adheres to FEM 1001 design standards.

- Rail span of 18–24m, A100 rail type or equivalent.

- Height: 12–13m.

- Moving length: +/- 100m or longer according to actual port conditions.

- Travel speed: 15~20m/minute.

- Wheel load capacity: 25–35 tons/wheel.

- Cable reel: Conductix.

- Moving motor: 8 motors from Nord, Sumitomo, Siemens, and Bonfiglioli, similar to existing crane motors.

- Seaside atmospheric conditions at Wind Force 10 and above.

- Wind pressure during operation: 20m/s.

- Wind pressure at rest: 63m/s.

Crane Base Construction:

- The steel structure uses Q345B steel and is manufactured to meet the required standards.

- Welding quality adheres to AWS D1.1 standards, with welders certified at least 3G, 4G international standards (PQR/WPS).

- All welded joints on the steel plates undergo 100% UT ultrasonic testing.

- Due to exposure to seawater, the cleaning process must achieve a minimum Sa2.5 according to ISO 8501. The paint used is zinc-rich epoxy with a minimum paint layer thickness of 240 microns.

- Steel structure design must withstand wind speeds of 20m/s during operation and 63m/s when not in use.

Other Crane Components:

Moving Assembly:

- Crane wheels must be made from at least S45C mechanical steel, with surfaces ground and roller burnished.

- The surface must achieve a minimum hardness of 45HRC.

Control System for Crane Base:

Integrated with Mitsubishi, Yaskawa frequency converters, and PLC, along with a safety control system for the entire crane, including wind warnings, operation bells, moving lights, intercoms, and emergency stop systems.

VINALIFT Quality Assurance:

Design Team:

- Mechanical and automation design teams at VINALIFT have over 15 years of experience, having worked on numerous significant projects exported to the US, EU, and Japan.

- Crane design calculations are performed using platforms such as Ansys and SAP2000.

- Collaboration with experts in port equipment from the University of Construction.

Production Factory:

- Factory area: 20,000m2.

- Key production processes include plasma CNC cutting for preliminary shaping, welding using approved procedures (PQR/WPS), and steel structure cleaning according to Sa2.5 standards.

- Mechanical processing workshop equipped with various machinery, including large-sized German-imported CNC milling machines for processing crane balancing beams and wheel hub boxes.

Installation Capability:

- VINALIFT has proven its installation capabilities through the completion of challenging projects where space constraints, low surface pressure on port structures, and extensive crane placement were overcome.

- Maintenance space, easily accessible for inspection and upkeep.

Specialized Training:

Engineers at VINALIFT, along with manufacturer training, have been extensively trained in crane maintenance, ensuring quick operational deployment without compromising efficiency.

Notable Projects:

In conclusion, the CBG 360, a 50-ton rail-mounted crane with a 36m reach from Liebherr provided by VINALIFT, is a state-of-the-art solution designed to meet the growing demands of modern ports. With its efficient design, robust construction, and advanced features, this crane ensures high-performance cargo handling, making it an ideal choice for ports dealing with large cargo ships. VINALIFT’s commitment to quality, from design to production and installation, positions it as a reliable partner for those seeking top-notch port equipment.